The staircase is a complex architectural element. Any house owner wants it to serve long, be safe and comfortable, have an aesthetic appearance, and not require specific care and constant repair. Among other materials used for the manufacture of stairwells, concrete meet these requirements more than others. This artificial stone is a clear leader in strength and durability.

Arrangement of a staircase with your own hands: basic moments

The procedure of arrangement of the concrete staircase is divided into four stages:

- design and specification;

- assembly of formwork;

- installation of reinforcement framework;

- pouring of concrete.

Every stage has its own specifics and difficulties. The most complicated stage is the assembly of formwork with your own hands. Arrangement of formwork is a laborious process that requires certain skills. If you’re going to build a staircase with a complex configuration, you should entrust it to the professionals.

If you decided to build a construction of a simple geometric form, if you have the skills in working with concrete, you can do it with your own hands. To that end, you will have to perform all the above-mentioned stages on your own (starting with the design).

How to perform calculations correctly?

When creating the project, you need to consider a few parameters:

- inclination angle and length of the staircase;

- size of steps;

- width of flight;

- features of fastening.

The most comfortable inclination angle is 30⁰-45⁰. It is not appropriate to make a steeper slope in residential buildings. Exceptions are the cases when you need the steps to the rarely visited storage spaces.

If there is not enough space for the flight with such slope, it’s better to build a winding, L- or U-shaped staircase.

The choice of inclination angle is the first step in design, as it will define the length of the staircase. The width of the flight depends on specific conditions. However, it can’t be less 90 cm.

The optimal height of the riser is 15 cm. It is believed that this parameter requires the least effort for lifting. The width of the step can vary from 25 to 39 cm, while the optimal one is 30 cm. You can calculate this parameter on your own, considering that the comfortable width must be 70% of the length of the foot of the adult person.

Making calculations it is important to consider the width of floors and floor coverings. Concrete structures are installed during construction, up to the final finishing; therefore, the height of first and last riser must be calculated, taking into account the following floor laying.

Why do you need specifications and estimates?

The next step after the calculation of all parameters and making a drawing is a specification, i.e., the calculation of the required amount of materials and their brands. The price of the staircase will be minimal if you make such calculations in advance and don’t buy the unnecessary materials. It will also help you to buy all components for building with the necessary characteristics, as drawing up specifications, you will learn all the nuances in advance.

If you install the concrete construction with your own hands, you can determine the price at the time of cost estimations. After calculating the types and amount of materials (i.e., making the specification) and finding out their price, you will get the preliminary sum. To that, you should add the cost of delivery of the building material and rent of concrete mixer, if you decided to make a solution with your own hands. If you’re going to hire an accomplice, you should consider his salary. By adding all the components together, you will know the full price.

Arrangement of formwork with your own hands

To make the staircase smooth and beautiful, you should prepare rigid and solid formwork for filling. To avoid the leakage of laitance, it must not have slots and gaps. You should use such material as water-resistant (laminated) plywood with a width of at least 10 mm. You also need to prepare the boards for horizontal steps. They must be strong, as they take on the main load of the whole structure and poured solution.

Joints can be sealed with tile adhesive. It is made to prevent scarring after hardening and facilitate the subsequent finishing works. Plywood formwork must be reinforced with aboard. The whole formwork should be fastened to withstand the load of concrete, and its elements don’t shift with respect to each other.

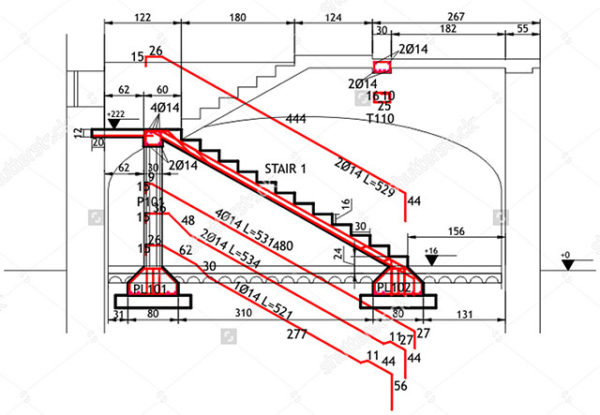

At first, you should install the pallet, i.e., the formwork, limiting the bottom of the staircase, and then make a flange. Boards outline the side border and serve as an attachment point of subsequent elements. After flanging, you should build the reinforcing cage with cells (200×150 or 200×200). Transverse reinforcement is fixed in the holes in the adjacent wall. After arranging the frame, you can mount the formwork of steps, attaching it to the wall with metal squares.

How to pour the solution correctly?

For the fill, you can either use a ready concrete or make a mixture with your own hands. To make a mixture, you will need the cement (М350), sand, rubble, and concrete mixer. You should pour the ready solution starting from the lower steps. After every 2-3 steps, you should make the cuts to fill all voids. The best way to do that is with a vibrator. The solution, squeezed through the formwork, should be moved upwards. Using the trowel, you should give the final form to the step.

Filled solution “ripens” for about three weeks. Only after that period, you can remove the formwork. All this time, concrete must be moisturized about twice a day. There is another option for preventing water loss – to cover the concrete structure with plastic. In winter, plus temperature shall be maintained in the room where the staircase is installed. It is important to keep in mind that hardening takes three weeks at the temperature of +18º – +20º, so the lower the temperature, the slower consolidation, and strength set goes.

Was this article useful for you? Tell us what other nuances we should consider? Which topics do we have to disclose? If you want to build formwork and fill the stairs on your own, we recommend the materials uncovering the secrets of reinforcement of the staircase.

By creating a specification that outlines the required amount of materials and their brands, you can ensure that you purchase only what is necessary and avoid unnecessary expenses.