Universal ladders-transformers are practical and very convenient because they can perform the functions of the various equipment. The compactness and portability of the ladders make it easy to transport and move them from place to place.

Functions of transformers and structural features

Thanks to the special design transformers are ideal for different types of work – commercial work, repair work and installation. Articulated ladders can be of the following configurations, but the operating altitude will vary in each state:

- side-ladders (from 4.3 to 4.7 m);

- L-shaped ladders (3,0-3,3 m);

- U-shaped ladders (1.2-1.5 m);

- regular ladders (2.2 m).

Standard aluminum ladders (4×4) have 4 sections and the same number of steps. Locks-fixators and a pair of reference tags are needed to make it more stable; different models may have 2-3 sets of locks.

Why do we need transformers?

Advanced functionality makes the ladder ideal for repair of any complexity, household and special works. Thanks to universal designs, repairs can be done with your own hands without buying expensive professional equipment.

Where is a ladder-transformer used?

- finishing of ceilings and facades, installation of the roof and drainage systems;

- installation of various types of lamps and partial or full replacement of electrical wiring;

- installation of stands and terraces in the garden, planting;

- access to attics and shelves.

Articulated ladders-transformers are conveniently used at public places to facilitate access to the places of storage of various goods.

Universal ladder are as efficient as possible on any curved surfaces because the hinges adjust the height and tilt of each element of the structure.

How can you choose a reliable ladder-transformer?

Pictures of products in this article do not give a complete picture of the functionality and performance of the goods. When choosing, pay attention to the key factors:

- the strength of the fastening elements (locks, rivets) and no damages on the surface of the racks;

- the surface of stairs must have a clear corrugation without “blur”;

- correct geometric shape of the structure is another important item, so it is better to unpack the ladder and see it in action before buying;

- tight fit of the base of the transformer to the surface can not only visually inspect; shaking the ladder to the right and to the left, you need to follow the lack of gaps;

- base material should not be slippery to make the stairs safe and comfortable.

How much does a transformer cost?

Average price of equipment includes the cost of materials, the working height and functionality. Popular European construction brands sell products at prices 20-30% higher than domestic companies – from 8000 to 40 000 RUB. A ladder from the less promoted brand will cost much cheaper, a standard transformer will cost 5000 – 7 000 RUB

The purpose of a ladder (professional or business) also affects the price. Models of the first category can cost several times more than the others.

Materials for folding constructions

Below are the most popular materials for the manufacture of mobile ladders.

Aluminium

The most popular articulated ladders are made of aluminum, they are quite light, but quite durable. If you have the required parts, you can assemble an aluminum ladder, even with your own hands, not forgetting about the anodization of surfaces and subsequent coating with aniline dyes.

Steel

If we talk about the nearest competitors of aluminum construction, we mean steel or fiberglass transformers. Steel is mainly used in professional equipment where multiple loads are assumed. Repair steel ladders are too bulky for household jobs and DIY, they are difficult to move from place to place.

Fiberglass

Fiberglass ladders are used for work with electrical wiring when you need to eliminate the possibility of current flow through the elements of design. In other cases, the overpayment for the material is unlikely to be justified.

A good alternative to make the structure with the dielectric qualities is all kinds of pads and stickers made of rubber or polymers.

The ways of usage of constructions

Universal swivel designs are usually manufactured in 3 variants – 4×3, 4×4 and 4×5, where the first digit indicates the number of stages and the second one – the number of sections.

As a rule, having decided to collect a ladder with their hands, the majority of craftsmen prefer the 4×4 option as the most convenient and functional.

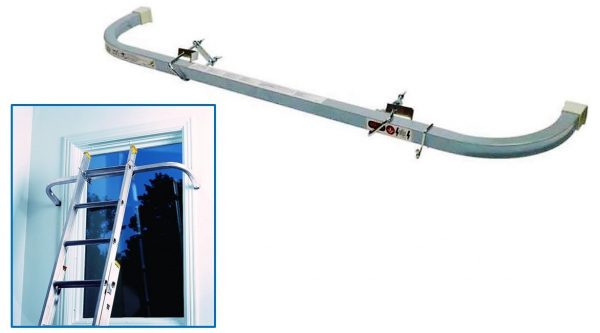

The hinged ladder can take the following forms:

- the form of the letter “V”;

- the form of the letter “U”;

- the platform;

- conventional side bearing.

The complete set of the most ladders includes a special surface that can be used as the basis platform or as a top platform for tools. The subsidiary items also include extenders racks and additional support required in high-rise works. It is possible to take into account when building structures with yous own hands.

Jointed design from different manufacturers may differ not only in price but also in their parameters.

Choosing the type of a ladder that can be assembled with your own hands, it is recommended to pay attention to the telescopic design. They do not require special components, and it will take no more than a couple of hours to assemble a ladder if you have all the necessary elements. You will need a few metal profiles and fasteners to assemble the ladder 4×4 with your own hands.

Self-assembly of constructions

If you want to install a standard ladder (4×4), you will need not only tools and special skills, but also drawings or photos of reliable designs.

Stages of assembly:

- You need to take a 4 round tube or square section for struts. Height is selected depending on the production needs, but the optimal length is 3 m.

- Measure distances for future steps on each of the supports, it is important that they are mounted at a right angle.

- Then you should weld the top and bottom the rails. Just after welding, the supports are fixed to the intermediate components.

- The last stage is installation of the indexing mechanism and pads on profiles. These details allow the staircase to open up and not crash into the ground at outdoor work.

It is easier to make and install a ladder with your own hands according to the ready-made drawing or a photo. Otherwise, you will have to calculate the load on each of the elements.

Durable and versatile transformers are useful in any apartment and home for different types of work. The variety of models and manufacturers gives the opportunity to choose a convenient and inexpensive design option. Your feedback about the features of selection and purchase will help to make the information more useful for many Internet users.